Since last week we know Samusng is going to use PHOLED inside their new Galaxy S IV. PHOLED is the next generation of AMOLED but you may ask, what is PHOLED and is PHOLED energy-efficient? We will explain this all. As we know Samsung uses AMOLED panels inside all new high-end smartphones. AMOLED is one of the greatest displays available in the market right now. In AMOLED panels each and every pixel is controlled. They switch off whenever they are not required or there is a black image on the display, this helps in increasing the battery life of the device. The only problem of AMOLED panels is the blue tint which is not good and sometimes the colour contrast is way too high which makes the colours look unreal. Samsung, the biggest OLED user is always busy with the development of new AMOLED / PHOLED panels. Together with Universal Display, Samsung is able to create next-gen of AMOLED panels. These PHOLED panels are much more efficient and the colours are stunning. Below we have copied some of the main features from Universal Display, the company also has patents on the PHOLED material.

WHAT IS PHOLED

A PHOLED phosphorescent OLED is an OLED that has up to four times higher efficiency than that of a conventional fluorescent OLED. OLEDs are monolithic, solid-state devices that typically consist of a series of organic thin films sandwiched between two thin-film conductive electrodes. When electricity is applied to an OLED, charge carriers (holes and electrons) are injected from the electrodes into the organic thin films. Then, under the influence of an electrical field, these carriers migrate through the device, until they recombine forming excitons. Once formed, these excitons, or excited states, relax to a lower energy level by giving off light and/or heat. With conventional fluorescent emission, only about 25% of the excitonic energy generates light, with the remaining 75% lost as heat. Through the use of certain phosphorescent materials, our university partners at Princeton University and the University of Southern California discovered in the late 1990s that up to 100% of the excitonic energy could be converted into light. This discovery was a major breakthrough. It meant that OLEDs could be up to four times more efficient than previously through possible – enabling OLEDs to compete today with LCDs as well as incandescent and fluorescent lighting in the future.

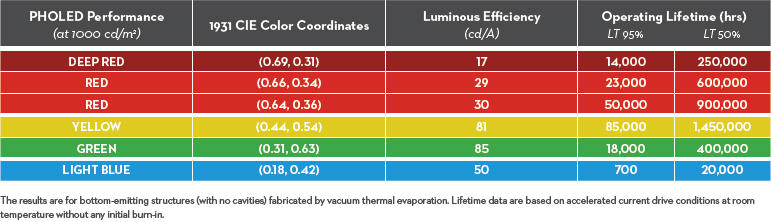

FEATURES AND PERFORMANCE

Our patented UniversalPHOLED® phosphorescent OLED (PHOLED) technology and award-winning materials are integral to enabling low power consumption in OLED displays and lighting. With luminous efficiencies that are up to four times higher than with fluorescent OLED materials, PHOLEDs also reduce heat generation and enhance the number of AMOLED backplane choices. These important PHOLED advantages allow OLEDs to compete with LCDs and conventional light sources. Universal Display continues to demonstrate advances in its UniversalPHOLED technology and materials. As shown below, we unveiled advances in luminous efficiency and operating lifetime for a number of our color systems at SID 2012. Today, our reds and greens offer extremely long lifetimes under a variety of operating conditions, and our blues continue to improve toward commercial entry targets. Our enhanced light-blue phosphorescent OLED emitter system with a 2x improvement in lifetime offers the potential for significantly reduced power consumption and extended operational lifetime in OLED devices for both display and lighting applications. For lighting applications, it may accelerate the introduction of a variety of initial commercial products where high-efficacy, warm-white emission is important. The new system also offers key performance advances for displays when used in Universal Display’s new four sub-pixel format. PHOLED technology and materials are well suited for use in a variety of manufacturing processes. A number of our PHOLED materials have been tested on commercial vacuum thermal evaporation (VTE) manufacturing equipment – demonstrating the extended cycle times needed for high-volume production. PHOLEDs are also compatible with OVPD™ organic vapor phase deposition, laser induced thermal imaging (LITI) and other novel deposition/patterning techniques, including ink jet printing, currently under development. PHOLEDs may be an excellent “green” solution for displays and lighting. With increased energy efficiency, PHOLEDs can reduce the demand for electricity and non-renewable fossil fuels. Also, OLEDs may significantly reduce the waste and disposal issues commonly associated with CRTs and fluorescent tubes.

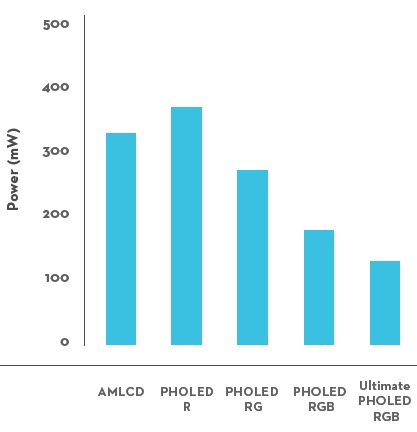

POWER CONSUMPTION

UniversalPHOLED technology and materials have become recognized for their key role in making OLEDs well suited for battery-operated mobile devices, such as smart phones, as well as for large-area TVs and white lighting. To demonstrate this advantage, we have modeled the power consumption of an active-matrix OLED (AMOLED) using our UniversalPHOLED technology and material, as compared to an AMLCD. Based on a 4” diagonal display, operating at 300 cd/m2 with video rate (40% pixels on), the power savings are significant.

Low temperature rise

Because electrical energy that is not converted into light is converted into heat, displays and lights generally experience a temperature rise while operating. This elevated temperature becomes especially palpable in a large-sized OLED TV or lamp. PHOLED technology can dramatically reduce this increase. For example, the temperature rise in the FL-OLED TV would be about 30°C while the temperature rise would be reduced to 10 – 17°C with PHOLED technology (assuming a 40” diagonal AMOLED). A low operating temperature is very important. It prolongs OLED lifetime as degradation increases with increasing temperature. It also reduces the amount of air conditioning required to remove the generated heat – making PHOLED technology an important element in any “green” or environmental building strategy.

Backplane compatibility

Today, amorphous silicon (a-Si) backplane technology is the incumbent for AMLCDs, with a mature, low-cost installed manufacturing base. Low temperature polycrystalline silicon (LTPS), a relative newcomer, uses more complex and therefore higher cost processes. However, LTPS is higher performance – offering higher carrier mobility so that driving circuitry can be integrated directly onto the substrate for lower cost, esp. for small-area displays. In addition, as LTPS transistors can be smaller than their a-Si counterparts, they can ease the fabrication of very high resolution displays. Conventional wisdom has also suggested that the higher mobility of LTPS would be required to meet OLED's high current drive conditions. This was the case until PHOLED technology was developed. The lower current drive of a PHOLED reduces the current requirements of the TFT backplane, thus reducing its mobility requirements. As a result, PHOLED technology has become a key enabler for the possible use of a-Si backplanes in large-area displays. In the future, PHOLEDs may also help enable the adoption of lower-cost organic TFTs. Also, there is an increasing interest in pursuing metal oxide TFTs for display backplanes. Once again, the lower current requirements of our PHOLEDs lowers the power consumed in the backplane. As a result, our PHOLED technology should also work very well with metal oxide TFT technology as it matures into production.