According to a new report from famous analyst Ming-Chi Kuo, Qualcomm has stopped the development of SoCs that were being designed to be manufactured by Intel Foundry Services (IFS) using the 20A fabrication process. The new development could benefit Samsung Foundry as Qualcomm could now get the Snapdragon 8 Gen 4 manufactured by the South Korean chip giant instead of Intel.

The analyst didn't provide much info about why Qualcomm made this decision. However, many experts believe that the high costs of Intel's 20A process may have led Qualcomm to stop the development. Qualcomm can't afford such high prices at the moment as the company is already struggling financially due to low sales of processors, which has been a direct result of poor smartphone sales recently.

The Snapdragon 8 Gen 4 was one of the chips expected to be made using Intel's 20A fabrication process, and the chip was expected to arrive next year. If the latest report from Ming-Chi Kuo is accurate, Qualcomm will neither design the Snapdragon 8 Gen 4 around the Intel 20A fabrication process nor get the chip made by IFS.

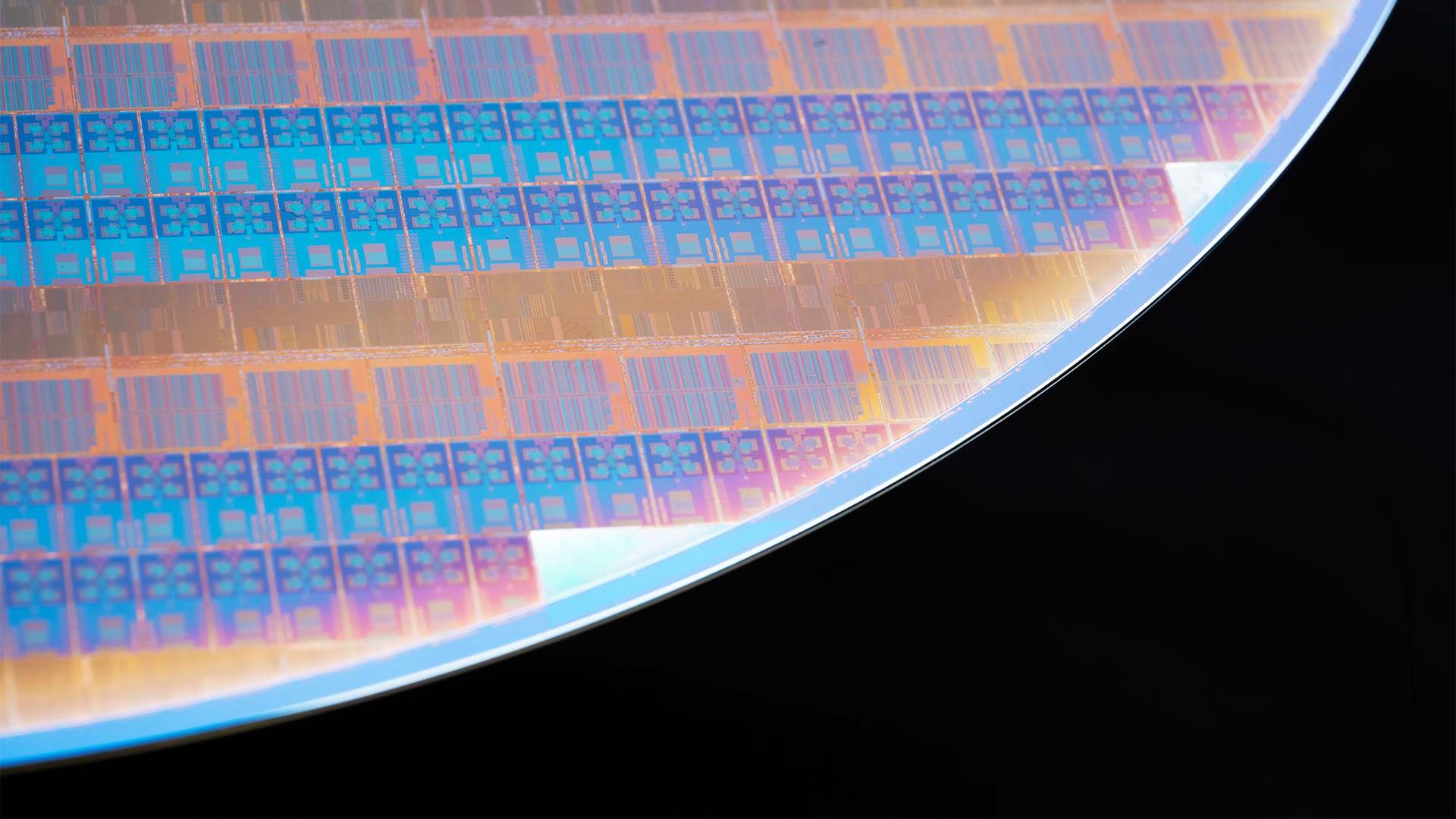

Apple has already secured the majority of TSMC's 3nm production capacity

In that case, Qualcomm will have to design the Snapdragon 8 Gen 4 on the next best fabrication processes, which currently are the 3nm nodes by Samsung Foundry and TSMC. However, almost 90% of TSMC's 3nm chip production capacity has already been secured by Apple for the Apple A17 SoC, which will be used in the upcoming iPhone 15 series.

That means, willingly or unwillingly, Qualcomm will have to get the majority of the Snapdragon 8 Gen 4 chips manufactured by Samsung Foundry on the company's 3GAP process. This is in line with what a previous leak had suggested. However, that's not a bad thing at all. The Snapdragon 8 Gen 4 chipsets manufactured on Samsung Foundry's 3GAP fabrication process could perform better than those manufactured on TSMCs' 3NE fabrication process.

Samsung's 3GAP process is reportedly more advanced than TSMC's 3nm process

The 3nm fabrication process from Samsung Foundry uses the GAA (Gate All Around) technology, which is superior to the conventional FinFET tech used in TSMC's 3nm fabrication process. On paper, GAA reduces current leakage, increases the drive current, and offers more precise control over the current flow. All these improvements should make the Snapdragon 8 Gen 4 perform faster while consuming less power.

In the past, Samsung Foundry has had low yields of chipsets made using advanced fabrication processes, such as 3nm and 4nm. That was one of the reasons Qualcomm preferred to go with TSMC for the Snapdragon 8+ Gen 1 and the Snapdragon 8 Gen 2. Fortunately for Qualcomm, Samsung Foundry has managed to increase the yield of its 3nm process to over 60%, which is believed to be better than that of TSMC's competing process. So, Qualcomm doesn't have to worry about Samsung Foundry's yield either.

The Snapdragon 8 Gen 4 manufactured by Samsung Foundry should not only be faster than those manufactured by TSMC but will also cost Qualcomm less. For once, it looks like Qualcomm will be better off choosing Samsung Foundry over TSMC. If Qualcomm indeed goes with Samsung Foundry, the South Korean tech giant will get a huge revenue and profit boost, helping the company when the foundry industry is going through its worst phase ever.

Some rumors claim that Qualcomm could dual-source the Snapdragon 8 Gen 4, using both Samsung Foundry and TSMC. Apple was among the few brands that dual-sourced its chips in the past. The A9 chip used in the iPhone 6s, iPhone SE, and iPad 9.7 (2017) was made by both TSMC and Samsung Foundry.