Calculating how much it costs precisely to make a smartphone is a tricky affair for third parties as companies don’t openly divulge component costs. Market analysts often rely on estimates from different sources to calculate the cost of popular smartphone models.

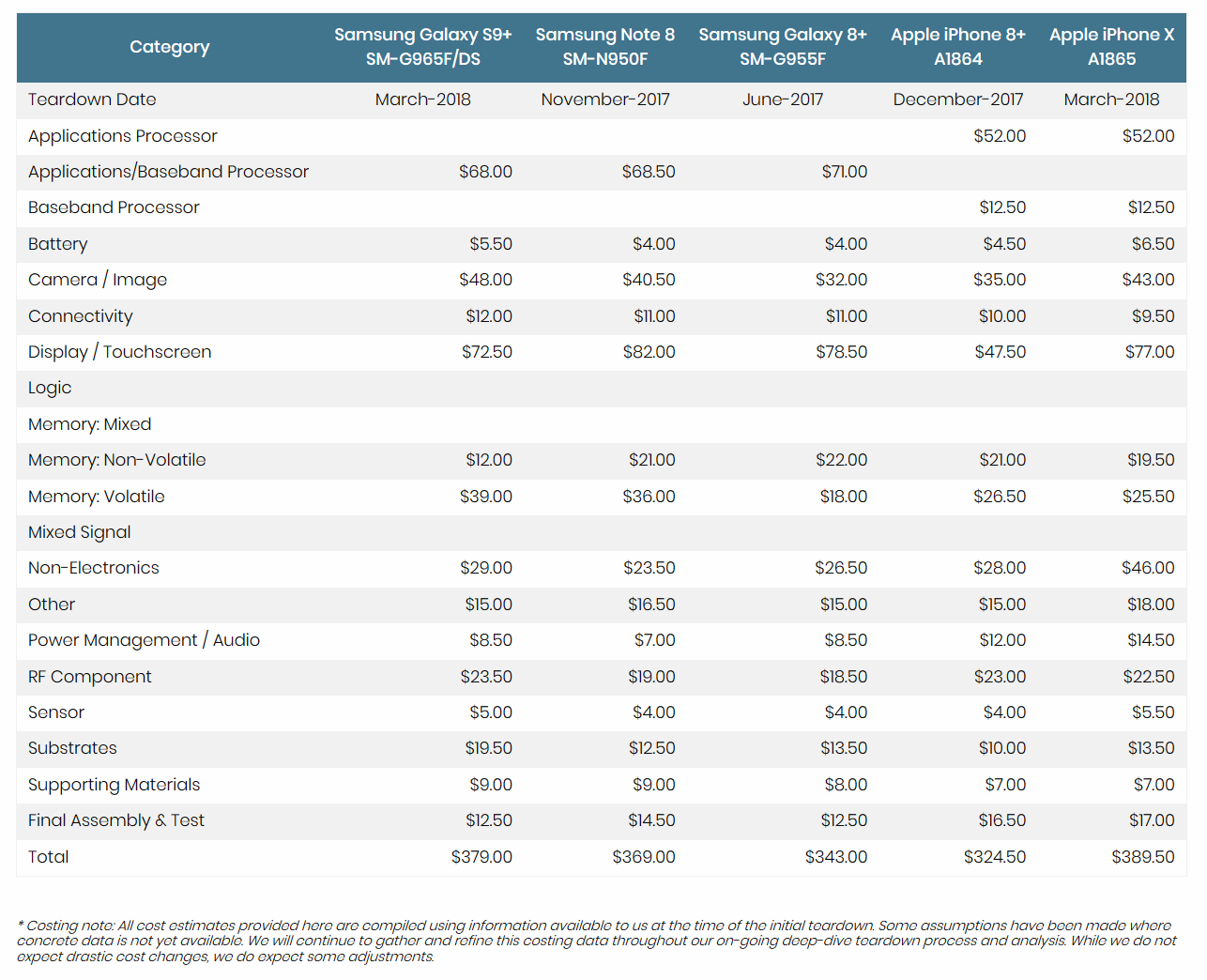

Techinsights has compiled a cost analysis of popular smartphone models in the market. While the cost comparison is based on estimates that may or may not be completely correct, it still represents the best guesswork we have on this topic. The analysis took into consideration various component prices to arrive at the manufacturing cost of the popular smartphones. The costs mentioned in the analysis is respective to the date of the teardown and have not been adjusted to reflect the current costs of the components.

The iPhone X tops the chart

According to the analysis, the Galaxy S9+ is more expensive to make than the Galaxy Note 8 even though the latter was priced higher than the Galaxy S9+ at launch. The report states it costs $379 to make the Galaxy S9+ compared to the Note 8’s $369. The iPhone X tops the chart at $389.5 while the iPhone 8+ costs $324.5 – the lowest among the group.

Samsung makes most of the components used in its smartphones, and so it pays some of these component costs to other divisions within the Samsung group. Apple, on the other hand, procurers many of its iPhone components from other suppliers, including Samsung.

Furthermore, the actual cost of the device to the companies is more than the sum of the price of the components as the final device cost involves other substantial costs such as R&D, marketing expenses, software development costs, distribution costs, etc.