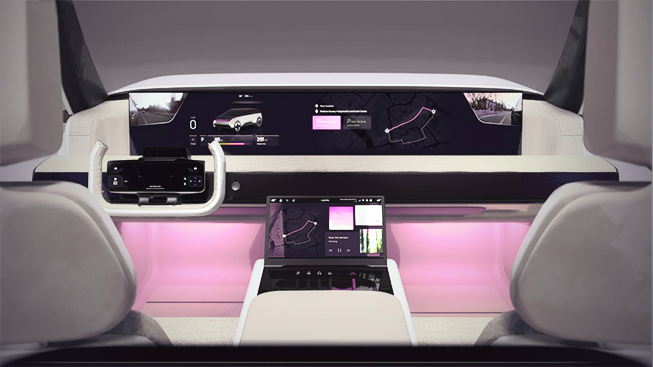

The two tech giants together with the aforementioned institutions share the same goal of tackling the semiconductor shortage across the automotive segment and establishing a stronger local supply chain. Samsung and Hyundai will reportedly cooperate on developing next-gen semiconductors, battery management chips, image sensors, and application processors for car infotainment systems.

This is a long-term plan with little benefits early on

Samsung is reportedly planning to develop high-performance automotive semiconductor products based on 12-inch wafers instead of relying on 8-inch wafers like the rest of the industry does.

Regardless, the automotive semiconductor market is not as profitable as the semiconductor space for mobile products in the short term, so this endeavor is meant to have long-term benefits.

Both Samsung Electronics and Hyundai Motor Co. are aware of the fact that they may not make a huge profit early on, but market watchers believe that their goal is to establish a stronger presence in the local automotive semiconductor supply chain as electric vehicles continue gaining popularity.

In parallel with the tech giant's semiconductor efforts, Samsung has recently unveiled its new PixCell LED intelligent headlight solution for electric vehicles. It uses ISOCELL-like pixel isolation technology to improve driver safety, and the company confirmed that it is already supplying these modules to car manufacturers.