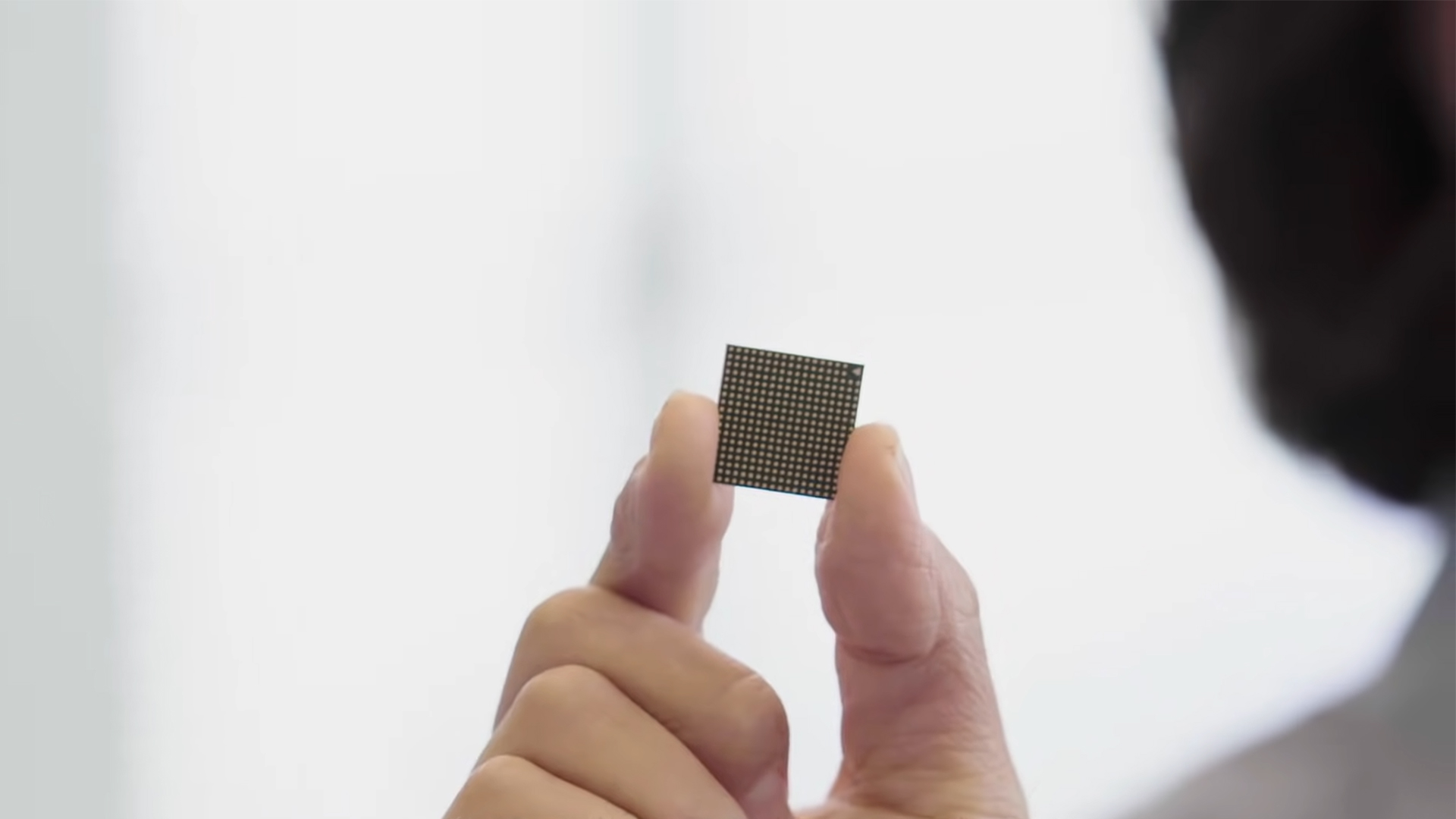

According to a new report, Samsung is currently evaluating whether it can convert its plant in Cheonan, South Korea, into a semiconductor chip factory. The plant was built in 1996 and was used by Samsung Display to make LCD panels. It consists of three buildings: L1/L2, L3/L4, and L5/L6. The L1/L2 building is not used for the production of LCD panels anymore, and the rest of the buildings have not been used for a few years anyway.

In 2018, Samsung Display leased some parts of the plant to Samsung Electro-Mechanics to make PLP (Panel Level Package), and the company had plans to utilize the whole facility. However, Samsung Electro-Mechanics did not see enough customers for its PLP, and it sold the business to Samsung Electronics. Right now, parts of the plant are used by various Samsung affiliates for the production of OLED panels (A1 line), LCD color filters, and Samsung SDI batteries.

Industry sources claim that tens of millions of dollars are required annually to maintain the plant. Since the plant is not being fully utilized, and building a new chip plant takes a lot of time (and permissions from the government), Samsung Electronics wants to convert the Cheonan plant into a chip factory. It has already conducted an evaluation to see if the plant can be converted into a foundry fab.

It was revealed that with necessary changes, the plant could accommodate two 300mm foundry lines, equivalent to the size of Samsung Foundry's S1 line at Giheung, South Korea. However, the L5/L6 building would need additional construction with an earthquake-resistant design, while L1/L2 and L3/L4 buildings need to be completely demolished and built from scratch.

Apparently, Samsung Foundry is considering expanding its 28nm and 14nm production since those processes are more profitable than 7nm and 5nm processes.